On July 25, 1909, Louis Bleriot laboriously flew across the English Channel in his heavier-than-air single-seat land plane. This pioneering flight was the symbolic beginning of general aviation. With this flight, Bleriot has almost fulfilled the primal wish of many people since the beginning of mankind, for freedom of flying. This type of metal construction is still built today, 120 years after Bleriot, using the state-of-the-art technology at that time and can be described as a proven foot-sick nose drill.

A bird that does not retract its legs after start to reduce resistance is footsick.

A single-engine airplane with a propeller on its nose is a nose drill that laboriously drills its way through the air from airfield to airfield. Its propeller is a loud, life-threatening double sword with poor efficiency. Its diameter is too small, the ground clearance too low, the speed too high. The entire fuselage, which is located in the fast axial propeller jet, gets in the way of itself, decelerating with its resistance proportional to the flow velocity squared. That’s why ships don’t have this nonsense. Their propeller is not at the bow, but at the stern. Water is taboo for these aircraft.

After Bleriot, the plagiarists came with the military and brought the apocalypse. These product pirates describe their foot-sick nose drills as tried and tested. Tried and tested means standstill, no further development. Reject and repress creative thinking. This gives others the chance to overtake.

Therefore, the question to the aircraft owners and pilots who dominate the market: Do you want to fly the old missions unsafely and uneconomically for another 120 years with a towing propeller on your nose? Others, who have recognized the signs of the times are flying safely as well as profitably into the future with modern designs and construction. They also take advantage of nature’s gift, the free and global infrastructure, water.

The year 2023/24. Just delivered, a foot-sick nose drill with a Rolls-Royce Propellerturbine, in riveted metal construction, struggles laboriously through the air, from airport to airport. A use on water is impossible. Missions are limited.

A high-performance nose drill with a strong propeller turbine and pressurized cabin struggles through the air from airfield to airfield. A use on water is impossible. Missions are limited.

The propeller must never touch the ground.

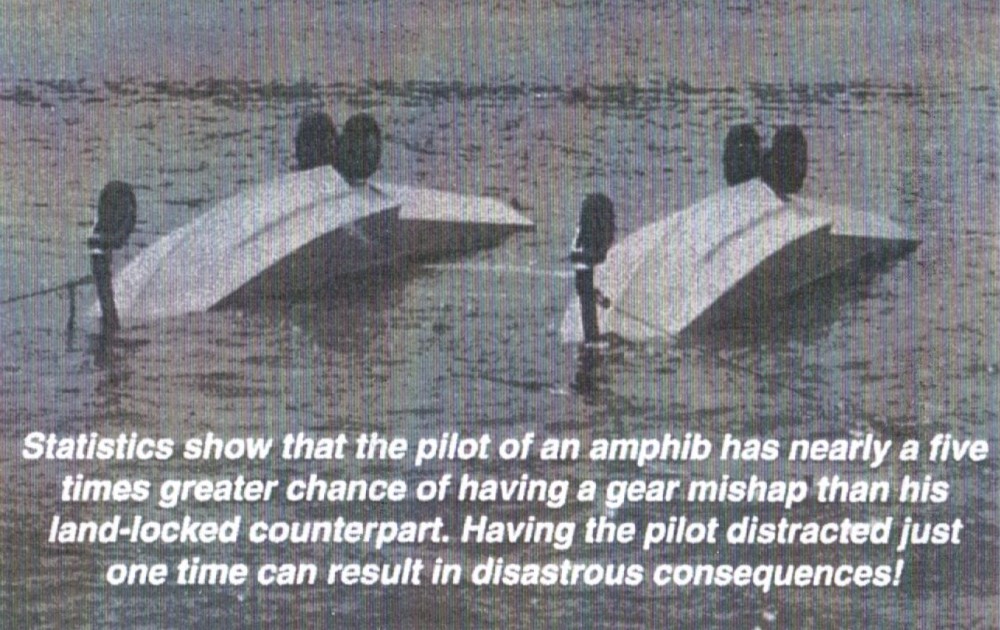

Usual daily routine, described by insurance companies as collateral damage

The propeller strikes mercilessly if taxiing is not controlled.

The classic, too hard landing leads to a rollover.

Water is not suitable for land plane to water on. Metal doesn’t float.

Floatplanes are not a solution for mobility on water.

Tragic

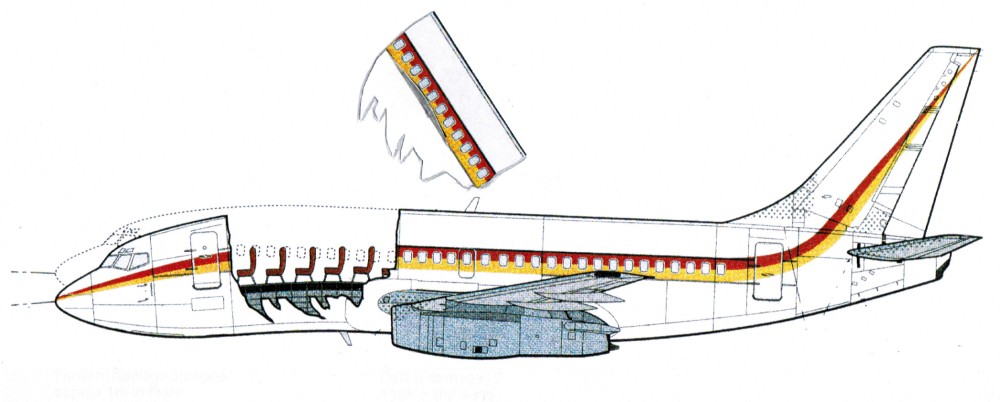

Boeing 737

On April 28, 1988, a Boeing 737 suddenly exploded at a high altitude over Hawaii without warning and lost an approximately 6 meter long fuselage part. The aluminum paneling tore like paper. The aircraft had not yet reached its calculated service life.

The joining technology of metal construction with riveting of finite aluminum sheets is the worst possible technology for mobile systems, such as aircraft, which are exposed to high long-term mechanical loads.

Their tendency to self-dissolve through corrosion begins at the molecular level in the factory before the first flight under rivets, overlaps, screw connections, varnish and paint.It is supported by the temperature difference between sea level, the cruising altitude and the formation of condensation.

Each row of rivet holes is a perforation line with a tear-off function like a postage stamps. The holes damage the crystalline structure of the aluminum and thus reduce its already low strength.

If an overstressed rivet fails, the chain reaction results in a disaster. The metal construction of aircraft therefore only has a limited lifespan.

B737 The same plane (as in previous image) after landing

After the successful emergency watering.

With the Equator Commuter, cockpit crews can realistically practice watering and the cabin crew practice evacuating passengers without panic breaking out.